Tel:+86-755-26890807

Email:export@goldsite.com.cn

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

loading

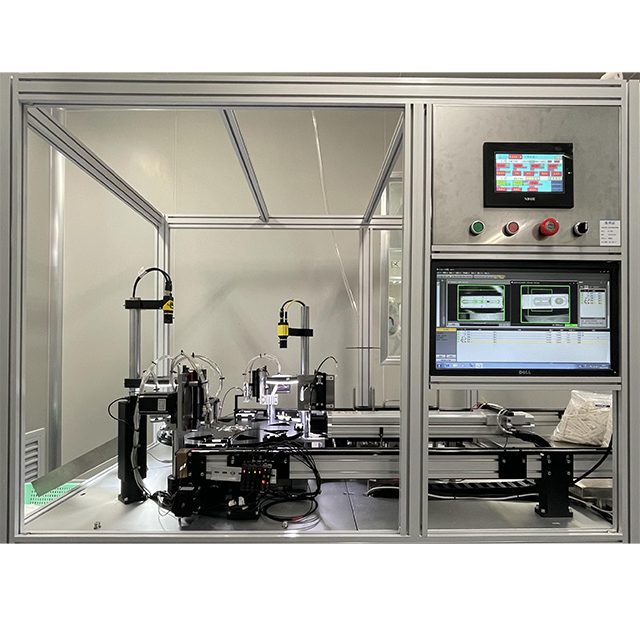

ACAM518

Goldsite

| Availability: | |

|---|---|

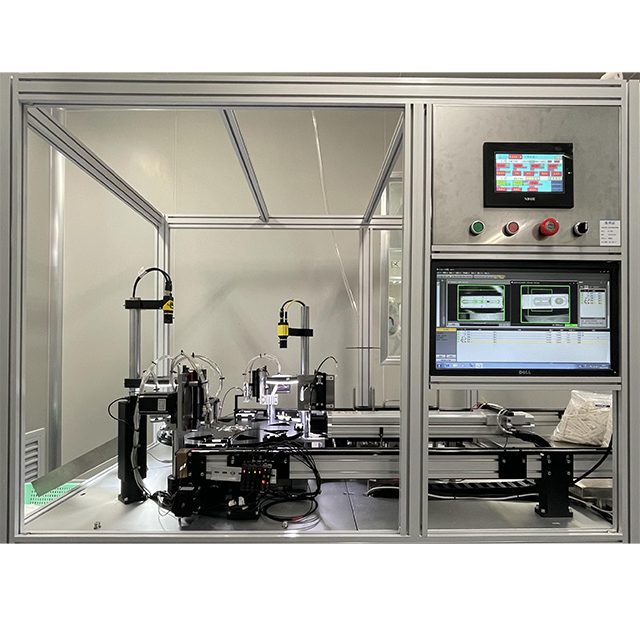

Compact size minimal footprint

High speed throughput while noise-free

Image recognition based vision inspection

Embedded industrial PC

Customized solutions

Budget saving

Easy to clean and has low maintenance

Suitable for all types lateral flow rapid test kit

| Speed | 30-40 pcs/min (customizable). |

| Dimension (L*W*H) | 1500mm*1000mm*1950mm (customizable) |

| Strip size | Length: 55~85 mm Width: 2.7~7mm (customizable) |

| Housings size: | Length: 65-100 mm Width: 18-28 mm (customizable) |

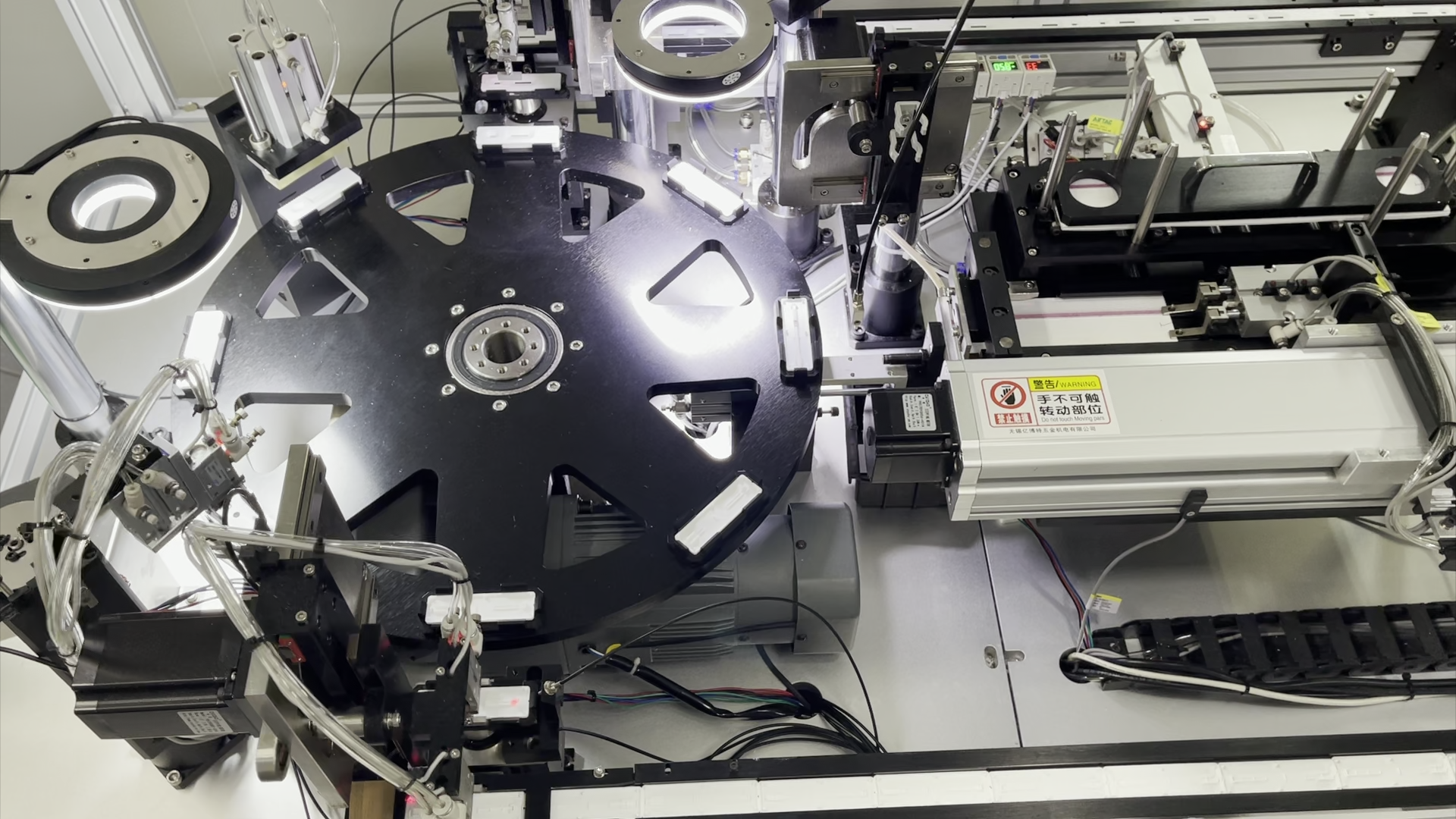

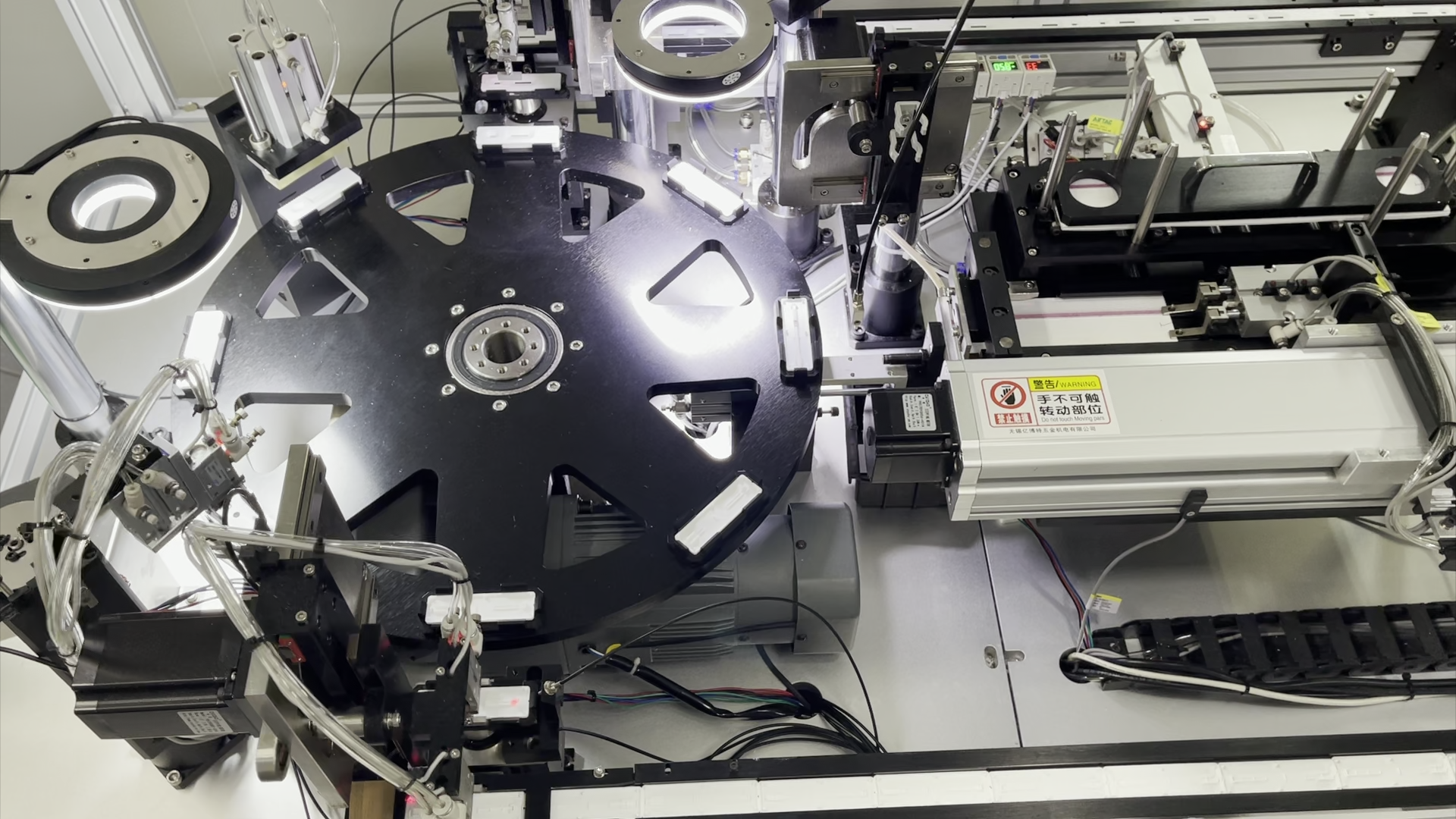

Housing press and assembly

Pressing the cap the bottom housing parts together

Precision cutting and loading of sheet strip

Housing parts feeding

Housing parts convey: Bottom housing and cap housing automatically convey belt.

Manual feeding or vibratory feeder feeding (customizable option)of bottom and cap housing part.

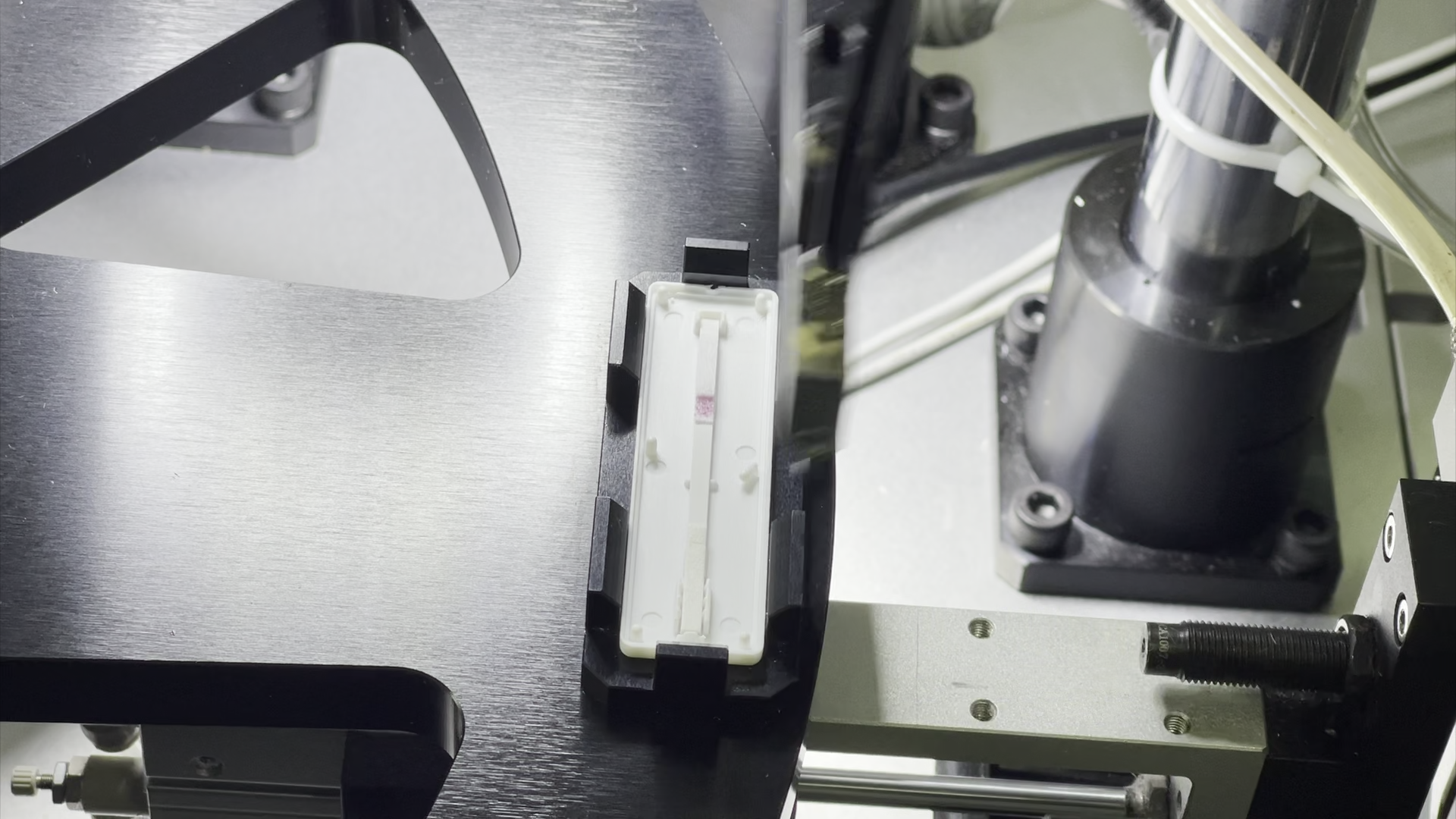

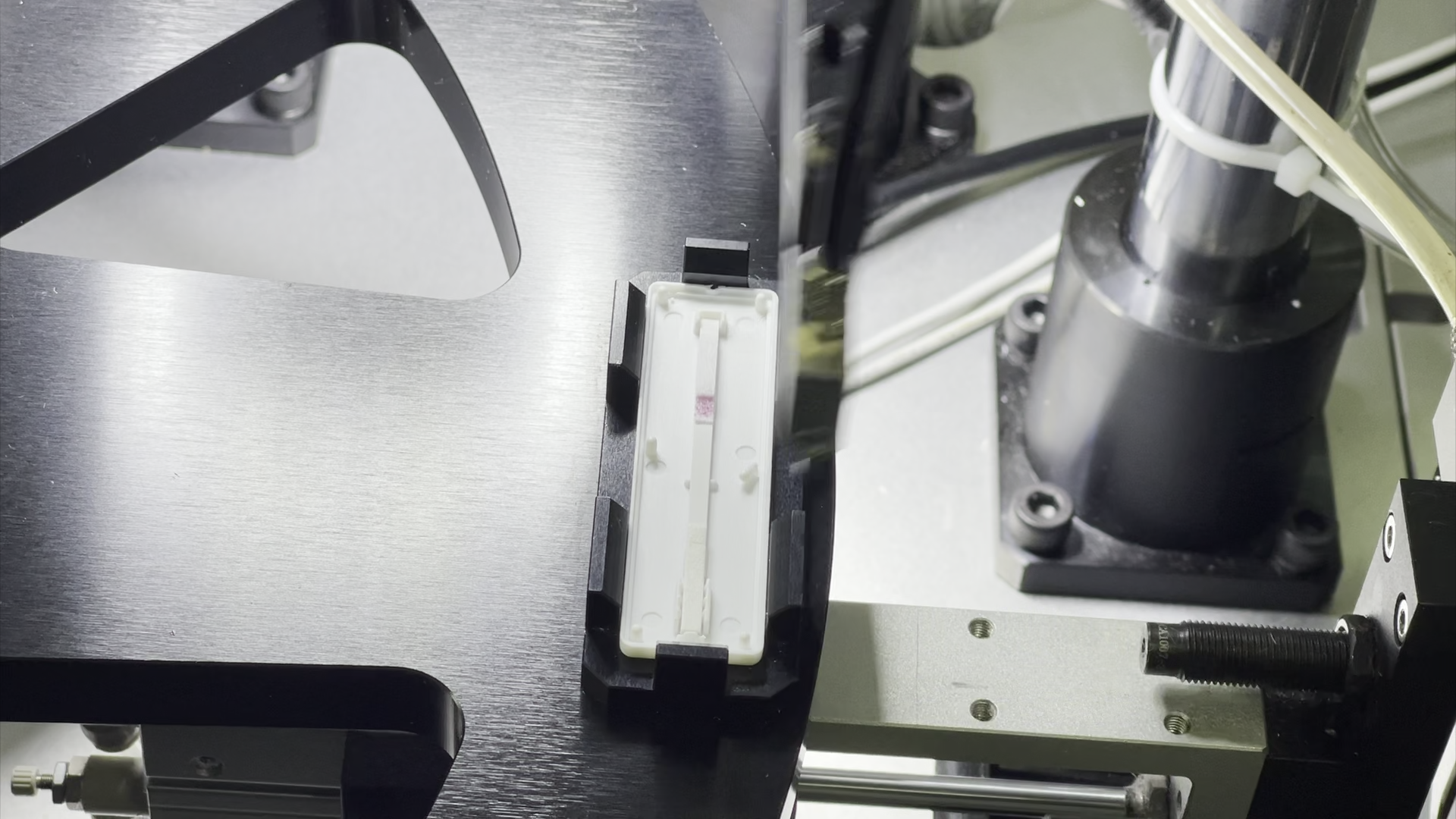

Image recognition based vision inspection

Ensure every finished products fits the quality control requirements.

Vision guidance system checks for faulty material, ensures precise strip width and the presence of strip before placement.

Auto inspection of positioning and orientation after assembly of housings. (Identification needs can be customized according to customer requirements)

Compact size minimal footprint

High speed throughput while noise-free

Image recognition based vision inspection

Embedded industrial PC

Customized solutions

Budget saving

Easy to clean and has low maintenance

Suitable for all types lateral flow rapid test kit

| Speed | 30-40 pcs/min (customizable). |

| Dimension (L*W*H) | 1500mm*1000mm*1950mm (customizable) |

| Strip size | Length: 55~85 mm Width: 2.7~7mm (customizable) |

| Housings size: | Length: 65-100 mm Width: 18-28 mm (customizable) |

Housing press and assembly

Pressing the cap the bottom housing parts together

Precision cutting and loading of sheet strip

Housing parts feeding

Housing parts convey: Bottom housing and cap housing automatically convey belt.

Manual feeding or vibratory feeder feeding (customizable option)of bottom and cap housing part.

Image recognition based vision inspection

Ensure every finished products fits the quality control requirements.

Vision guidance system checks for faulty material, ensures precise strip width and the presence of strip before placement.

Auto inspection of positioning and orientation after assembly of housings. (Identification needs can be customized according to customer requirements)

We offer